STAR CAM cutting nesting software

STAR CAM

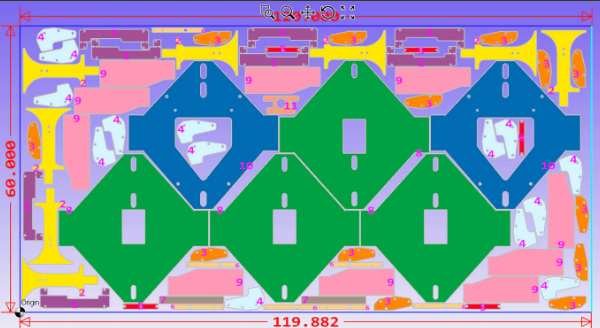

STAR CAM cutting nesting software, Fully auto nest; fully automatic intelligent common edge cutting (provides a variety of common edge cutting methods, cutting efficiency increased by 10% to 50%); Ful

STAR CAM cutting nesting software

I. STAR CAM product features:

1 Multiple functions

Available in a variety of nesting algorithms (real shape/rectangular envelope/pass-cutting/array)

Support for a variety of feeding modes (single sheet/batch/copy/residual/local filling/interactive)

Integrated data management (parts library/steel bank/statistical report)

2 Advanced technology

Fully automatic intelligent common edge cutting (provides a variety of common edge cutting methods, cutting efficiency increased by 10% to 50%)

3 Easy to operate

10 minutes to learn basic operation!

3 minutes output cutting code!

4 Independent copyright

With full independent intellectual property rights

To the well-known universities for technology support, to provide high-quality localization services

II STAR CAM product the main functions:

1 Cutting parts library management

2 Cutting steel plate library management

3 Automatic nesting

4 Interactive nesting

5 Cutting path optimization

6 Automatic programming and cutting simulation

7 Data summary and statistical report

8 Integrated solutions

Scope of application:

For cnc cutting machines, including flame, plasma and other CNC cutting machines, for any shape of parts of the drawing, programming, nesting, check and CNC cutting.

Purpose of use:

Improve the rate of nesting, effectively save steel, improve programming and cutting efficiency, effectively improve cutting production efficiency.

Key features:

A variety of formats file packages

Single or batch read into the file package

Set the part to be automatically wrapped as a matrix

The remaining plate or irregular sheet is fed

Multi-plate automatic continuous nest

Any manual nesting

Co-edged cutting function

Continuous cutting function

III Product Characteristics:

1 Easy to operate, with comprehensive training courses, training demonstrations and crash materials

2 A copy of the CNC cut file or on a USB stick to be cut

3 The nesting function is perfect, from manual, automatic, matrix, automatic tightening, to manual automatic interactive nest, fully combined with people's nesting experience and computer computing speed

4 Common edge cutting, improve the utilization rate of the dressing, save steel

5 Residual nesting, effective saving and reuse of surplus steel plate

6 Continuous cutting, effectively avoid or reduce preheating and perforation, save supplies, improve cutting efficiency