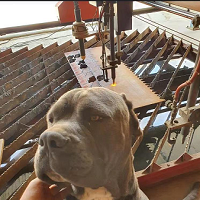

CNC System SF-2300S

CNC System SF-2300S

SH-2300AH / SF-2300S CNC System for Cutting is designed to work with Oxyfuel plasma in metal working.

System Functions

- Model SH/SF-2300S Series CNC System for Cutting is designed to work with Oxyfuel plasma in metal working.

- High reliability as well as good resistance to plasma disturbance, lightning and surge.

- Applied Oxyfuel plasma cutting technology, able to perform corner speed control and height control automatically;

- Kerf compensation, reasonability check and report for user's option;

- Breakpoint restoration, automatic power-back recovery and automatic breakpoint memory,

- Random section and piercing point selection,

- Extended piercing for thick plate and bridging feature for thin plate,

- Optional piercing position feature in mode of RETURN, SECTION(section selection) and RESBREK(breakpoint restoration), very convenient for user control,

- Ready for transitional cutting operation at any moment,

- Special short line machining feature based on smooth travel, extensively applicable to metal blanking as well as advertisement and ironwork fabrication, etc.

- Parts library of 24-type patterns, extensible and customizable, including the common machining parts,

- Compatible with many blanking software such as IBE(Germany), FASTCAM, etc.

- Operation menu in English, dynamic graphic display, 8-times zoom, free point automatic tracking, USB disk program and timely software upgrade.

Technical specifications

- Processor: Industrial ARM7 CPU

- Display: 10.4" Color LCD

- Input/output: 16 channels of optical isolation input and 14 channels of optical isolation output

- Interlocked axles: 2 axles, extensible to 4 interlocked axles

- Maximum speed: <24m/min

- Pulse equivalency: variable, electronic gear numerator and optional denominator in the range from 1 to 65535

- Memory space: 64M-512M oversized memory capacity for user program and no restriction to machining program

- Machine case size: 300*240*93(mm)

Operation temperature: 0 to +55; storage temperature: -40 to +60