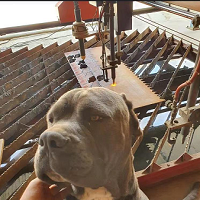

Plasma Portable Pipe CNC Cutter

CCL-TP

Suitable for round metal pipe diameter 40mm-320mm, plasma CNC cutting way, any 2D profile shape on metal pipe is available; meanwhile can add metal plate cutting function.

*Overall compact miniature structure

*Operation is small, nimble

*Can be for metal plate and pipe cutting both.

*Suitable for round metal pipe diameter 40mm-320mm.

Parameter:

|

Item |

Parameter |

|

CNC Control Axis |

2/3 |

|

Cutting pipe length |

3-12m or customized |

|

Chuck Size |

250# |

|

Cutting pipe diameter |

Φ40mm-Φ320mm(Or Customized) |

|

Max loading weight |

>800KG |

|

Pipe Ovality |

≤2% |

|

Running precision |

±0.2/m |

|

Torch up down distance |

130mm |

|

Flame cutting thickness |

Piercing:5mm-50mm/ Rim:150mm |

|

Plasma cutting thickness |

0.1-25mm |

|

Cutting Speed |

Flame cutting way 700mm/min Plasma cutting 0-6500mm/min |

Features

- The main body adopts the portable cross structure, host and pipe are arranged in parallel, the carriage is equipped with a mobile trolley device, a precision screw lifting device, a fixed clamping flame or a plasma cutting torch, the steel pipe clamp adopts the chuck type structure, the support uses the screw drive, movable, can lift and support round pipe.

- Cutting can be controlled by CNC control of movement and tube rotation, the end of the pipe and the hole is for automatic cutting.

- The Chuck drive adopts famous brand servo motor to ensure the running balance of the whole machine, long life, simple operation and high efficiency.

- This model is suitable for 40-325mm pipe diameter and does not require bevel function.

- CCL-TP Series portable CNC intersecting line cutting machine is a kind of steel pipe and non-ferrous metal pipe joint at the intersection of the hole, intersection line end, elbow (shrimp Festival) automatic calculation and cutting equipment.

- The equipment is widely used in construction, steel structure, chemical industry, shipbuilding, mechanical engineering, metallurgy, electricity and other industries of the pipeline structure of the cutting process. This kind of processing in the past mostly uses manual production model, scribing, manual lofting, manual cutting, artificial grinding and other backward and complicated operation process.