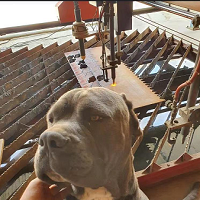

CNC metal cutting machine — Fiber Laser cnc cutting Machine

- Although high-power CO2 laser machines can also cut stainless steel, it has low efficiency and consumes much energy. Besides, the most common use of a CO2 laser machine is to process organic materials, like wood, acrylic, leather, fabric, and stone.

- Currently, most sheet metal cutting applications—especially below 6 mm—are mainly done by fiber cutting systems, CNC cutter limited also recommended you so. The fiber laser cutter is a kind of metal cutting CNC machine. It irradiates a high-density laser beam to the metal surface, and the energy released by the laser melts the metal. The laser head moves above the metal sheet along a certain route given by the computer to form a slit. Then certain shapes are cut off from the sheet.

- The fiber steel metal laser cutting machine adopts a non-contact-based cutting method. This method has a small heat-affected area and leaves no damage to the workpieces. The metal products cut by a fiber laser cutter have tiny heat deformation, excellent precision, and smooth surfaces. There's no need for further processing. The fiber laser beam provides a metal-friendly wavelength, and metal material can absorb the laser energy effectively. The small spot size and excellent beam profile make it ideal for cutting most metals.

- The photoelectric conversion rate of CNC cutter limited fiber laser sheet metal cutting machine can reach 30%. This can greatly save power consumption and the use cost is low. The laser beam has good quality and stable performance. The laser adopts optical fiber transmission mode instead of easily worn-out reflective lenses. So it basically does not need maintenance.